Lesaffre (France) Visits Single-Cell Center at QIBEBT for Industrial iMAPS Cooperation Talks

A senior delegation from Lesaffre, a global leader in industrial fermentation, visited the Single-Cell Center at the Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences (QIBEBT, CAS) on August 19 to discuss strategic collaboration in biomanufacturing. The visit focused on co-developing the “In-situ Metabolic Atlas Project @ Single-Cell” (iMAPS) for industrial applications and on advancing single-cell, metabolism-targeted microbial screening for strain development and fermentation control.

At the meeting, RU Zhitao, Deputy Director of the European Cooperation Division of the Bureau of International Cooperation at CAS, and Prof. XU Jian, Director of the Single-Cell Center at QIBEBT, delivered remarks. XU outlined the Center's technical capabilities, current progress in building the international iMAPS program, and its goal: to link real-time single-cell metabolic readout directly to industrial strain discovery and process optimization. Lesaffre representative Anne-Charlotte PUPIN presented the company's global R&D strategy and emphasized Lesaffre's commitment to using microbial potential to drive sustainable development.

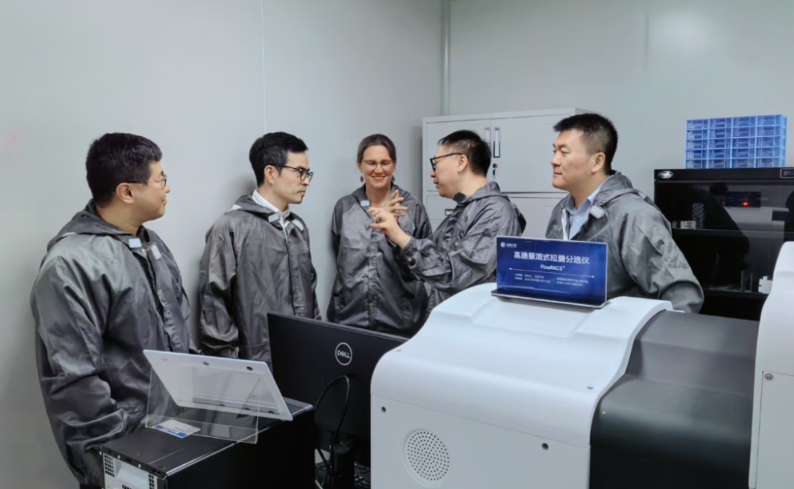

The delegation also toured Qingdao Single-Cell Biotech. Co., Ltd., QIBEBT's industrialization partner, for on-site demonstrations of the Center's original single-cell instrument suite. Showcased systems included: FlowRACS, a Raman flow cytometric sorting platform for precise metabolic analysis and sorting of functional microbial cells, which can be extended as RamanEye for real-time fermentation monitoring; RACS-Seq/Culture, a single-cell Raman optical tweezers system for capturing individual microbial cells and enabling downstream cultivation or sequencing; EasySort Compact, an AI-assisted microdroplet single-cell screening system using bright-field and fluorescence imaging; and the Digital Colony Picker (DCP), which supports high-density parallel cultivation and non-contact laser-based clone retrieval to accelerate strain industrialization.

According to both sides, integrating these platforms creates a full “single-cell to factory” workflow — from resource discovery and strain screening to fermentation optimization and technology transfer — and lays a foundation for deeper industry–institute cooperation in next-generation biomanufacturing.